Per Os Biosciences LLC

functional gum, chewable tablets,

lozenges, mints and candy

Manufacturing Health in a Tasty, Efficient Delivery System

nobody can do it the way we do it

Advantages of Room Temperature Process

for Gum Making

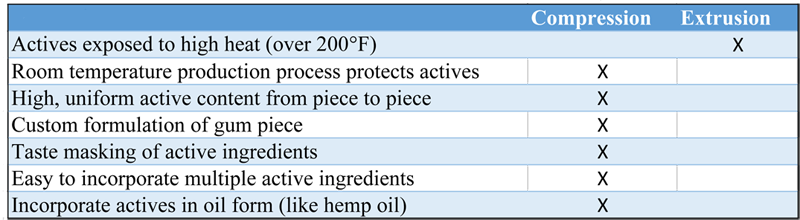

Per Os Bio uses a patented technology to manufacture its own powdered gum in what is know as a room temperature process. This allows for the flexibility to create custom formulations that can incorporate multiple gum bases and multiple active ingredients. Conventional gum manufacturers use an extrusion process that requires high heat which can kill many active ingredients and may result in a sub-potent final gum product. Per Os Bio’s functional gum is manufactured under GMP conditions at room temperature (Room Temperature Process) using pharmaceutical direct compression techniques so the actives are fully available in the final product.

The advantages of a compressed tablet gum versus the extrusion method:

About